The integration of a measuring sensor increases the efficiency, quality and accuracy of your high-speed erosion machine. Fields of application are the automatic work piece setup as well as testing and verification of work pieces and processes on the machine.

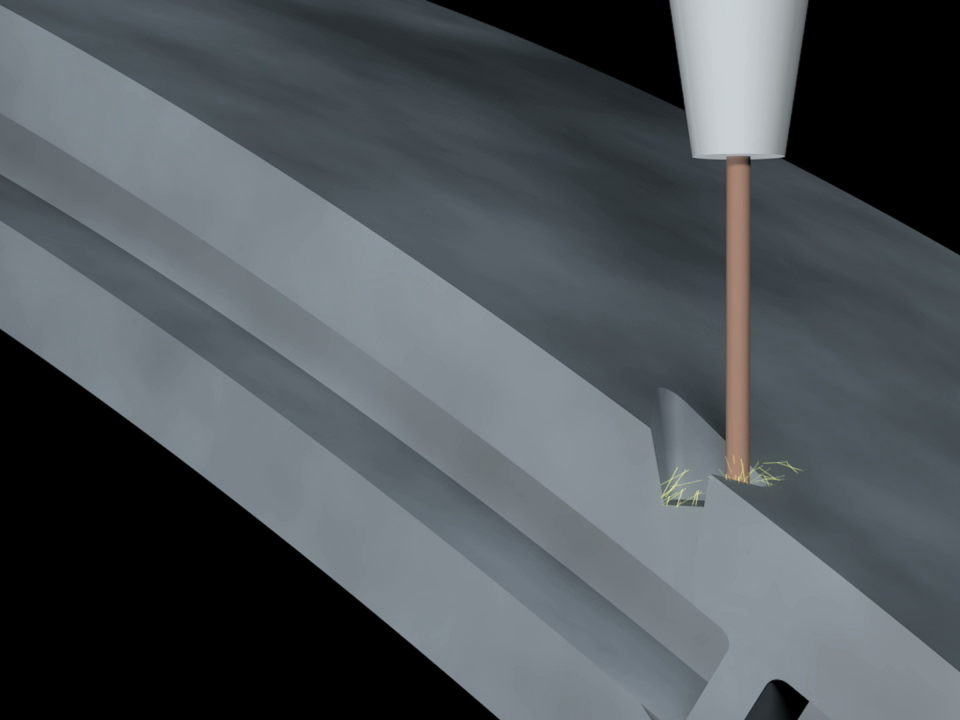

Due to existing deviations in the components and the increased precision requirements in machining, touching process is necessary. With the measuring sensor, this process is improved qualitatively and time is saved compared to manual operation! Since the repeatability of the measuring sensor is 1.0 μm, a more accurate positioning of the drill holes is achieved. The causes of process deviations are eliminated. In case of higher touching effort for the components, this procedure can result in a reduction of expenditure of time of up to 30%! Compliance with required tolerances is increased. Errors caused by manual entries are excluded. The quality of the work pieces, as well as the machining precision is improved and the efficiency of your EDM drilling machine is increased. The installation of a measuring sensor is not only possible on new machines, but also as a retrofit for your existing APos-Solid machine. No experience in measuring is required. Operation is simple and self-explanatory.

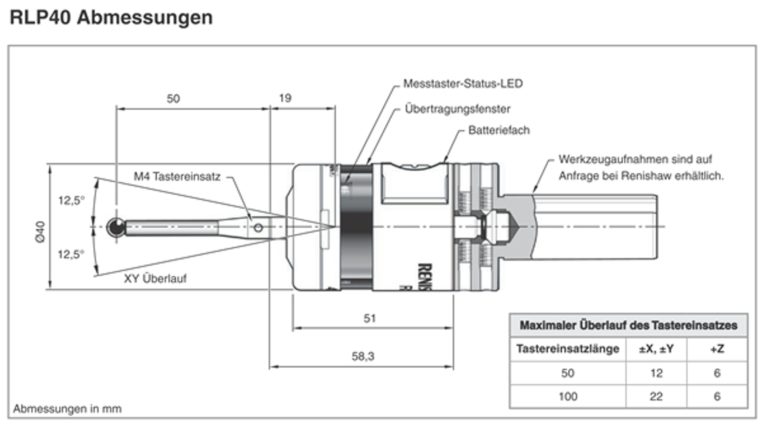

It is possible to have all measuring procedures performed in the program sequence like before. The coordinates are automatically stored in the selected zero point and can be used in the further process. The measuring sensor RLP40 from Renishaw is equipped with wireless signal transmission. The special features are the robust and proven technology, the compact design and the excellent communication performance. No specific radio channel is required. The signal transmission has a range of up to 15 m.

Even if there are other devices with transmission technologies, the measuring sensor operates without interference. Correct and reliable measurement is also carried out under difficult ambient conditions such as vibrations and temperature fluctuations.

At the EMO show in Hannover, we will present the latest developments on the APos high-speed EDM drilling machine. Come and visit us!