We develop solutions according to your requirements!

You need a special solution in the field of EDM? We offer hardware and software for special EDM machines. We are specialized on the construction of special machines. You give us your requirements – we develop proposals for solutions and bring the machines to perfection according to your requirements and wishes.

Already realized projects:

work piece diameter 2,000 mm

work piece diameter 2,000 mm

work piece weight 1 T

electrode diameter 2.8 mm

drilling up to the center axis with max.

Electrode length of 1,150 mm.

2,100 x 900mm

2,100 x 900mm

electrode length up to 1,150mm

work piece weight up to 8t

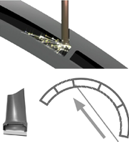

Heun is able to drill around the corner. A special process enables us to work the piece at points difficult to access, with bended and rotating electrodes.

Heun is able to drill around the corner. A special process enables us to work the piece at points difficult to access, with bended and rotating electrodes.

In the manufacture of turbine blades, coolant holes are required in extremely steep entry and exit angles. Even though the material thickness is not known, the breakthrough of the drilling without damage of the close rear panel has to be guaranteed.

In the manufacture of turbine blades, coolant holes are required in extremely steep entry and exit angles. Even though the material thickness is not known, the breakthrough of the drilling without damage of the close rear panel has to be guaranteed.

Rationalization / automation in a network together with EROWA, Hirschmann, 3R, AGIE, Roeders, Makino, Zimmer + Kreim, Zwicker has been realized.

Rationalization / automation in a network together with EROWA, Hirschmann, 3R, AGIE, Roeders, Makino, Zimmer + Kreim, Zwicker has been realized.

With a special machine from Heun the sensational drilling depth of 2,600 mm has been reached with an electrode diameter of 3 mm.

With a special machine from Heun the sensational drilling depth of 2,600 mm has been reached with an electrode diameter of 3 mm.

The challenge is not to drill holes, but to carry out geometries and surface abrasion. Special cooling channel structures are required for turbine blades. On the same machine as it is on a machine.

The challenge is not to drill holes, but to carry out geometries and surface abrasion. Special cooling channel structures are required for turbine blades. On the same machine as it is on a machine.