APos 800 CNC / APos 1200 CNC

High speed small hole EDM drilling machine with PC control System

For the machines of these series a completely new layout was designed in co-operation with company Abacus GmbH. The machine body is made of mineral concrete. The main features and advantages of this new conception are:

For the machines of these series a completely new layout was designed in co-operation with company Abacus GmbH. The machine body is made of mineral concrete. The main features and advantages of this new conception are:

- High stiffness and thermal stability

- Fully cased working area

- Axes compensation

- Intelligent tool handling

- High power generator for best drilling results

- Completely manufactured in Germany

- Large package of options

- Robot connection

- EDM milling

- And much more…

The new machine body is an especially developed, modular construction. The usability of the machine series is improved again by rearranging of the layout. Control system and generator are now placed in two separate electrical cabinets. Altogether a compact construction with small required space has been developed. The new housing, made of stainless steel meets highest safety standards. It can optionally be used as basin for machining in water or oil.

Technical Data APos 800 & APos 1200

| APos 800 | APos 1200 | |

|---|---|---|

| Travel X/Y/Z/W | 800 x 600 x 600 x 700 mm | 1200 x 600 x 800 x 700 mm |

| Max. work piece weight | 3000 kg | 3000 kg |

| Machine dimensions WxDxH | 1400 x 2200 x 2400 mm | 1400 x 2200 x 2500 mm |

| Machine weight | 3000 kg | 3300 kg |

| Rough adjustment Z-axis | 20 – 600 mm | 50 – 800 mm |

| Controlled W-axis | 700 mm | 700 mm |

| For electrode diameter | 0,1 – 3,0 mm, optional till 6,0 mm | 0,1 – 3,0 mm, optional till 6,0 mm |

| Usable electrode length | till 800 mm | till 800 mm |

Examples of use APos

| Examples of use | Pictures |

|---|---|

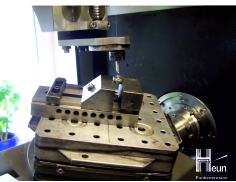

| Tool manufacture |  |

| Connection drilling |  |

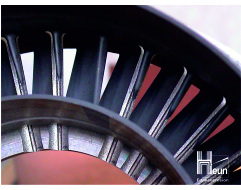

| Turbine blade |  |

| Turbine |  |

| Deep hole drilling |  |

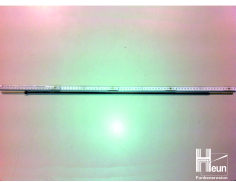

| Deep-hole drill internal cooling channel |

|

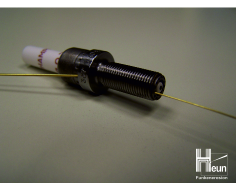

| Temperature sensor |  |

| Rock drill |  |

| Cutting punch |  |

| Forging die exhaust boring |

|

| Taper reamer wash boring |

|

| Taper reamer |  |

| Sample machining |  |

| Sample processing |  |

| Cutter head |  |

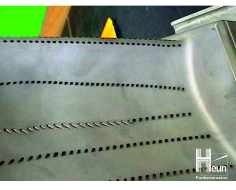

| Punched plate |  |

| Vane |  |

| Cooling hole |  |

| Bone screw |  |

| Bone drill |  |

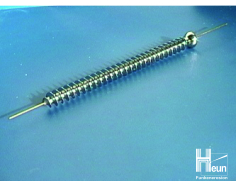

| Screw tap internal cooling |  |

| Mould making vacuum hole |  |

| Profile tread design |  |

| Injectors |  |

| Nozzles |  |

| Pressure absorber sensor hole |  |

| Turned parts |  |

| Pin |  |

| Diesel injection valve |  |

| Dental needle |  |

| Ejector pin |  |